Cladding of the buildings can be selected from several versions. Each of the versions has its specifics in terms of different physical and technical parameters and demands for the implementation of the construction.

The selection of the cladding version depends on the specific conditions of the construction under consideration.

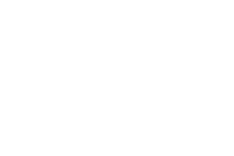

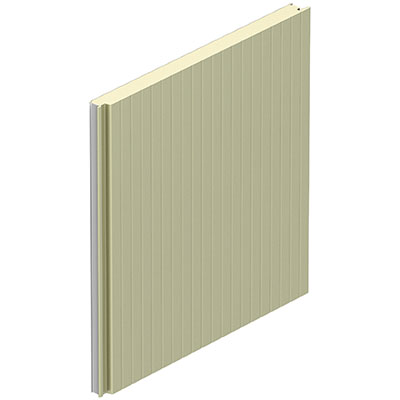

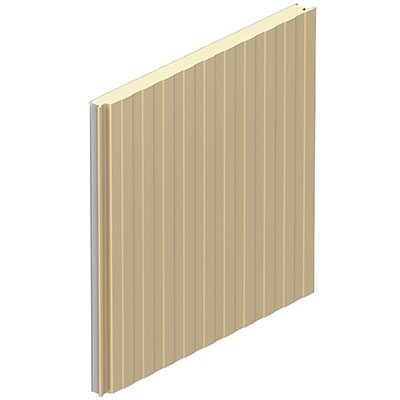

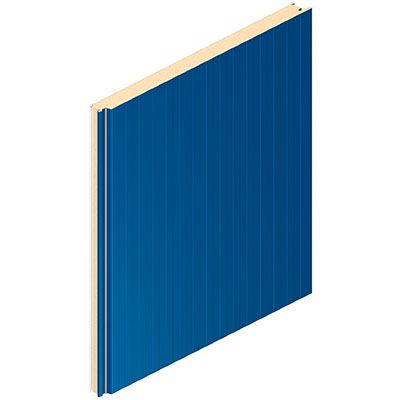

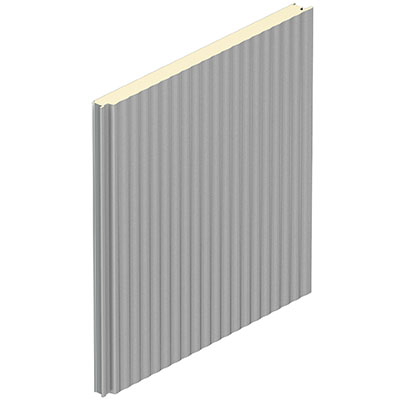

Sandwich panels are the most frequently used types of cladding of steel structures of our halls. The type of the panels is selected based on the specific requirements. The selection of the types of the panels depends on the requirements for heat insulation, technical, fire protection, and possibly acoustic properties. Sandwich panels enable us to offer a wide range of surface profiling and color scheme solutions to our customers.

Structural width of the panels is usually 1000 mm or 1150 mm.

The panels are laid vertically or horizontally.

| PANEL SPECIFICATION | POLYURETHANE PANELS | MINERAL PANELS |

|---|---|---|

| Thickness d (mm) | 40–200 mm | 60–200 mm |

| Application of the panel (mounting) | vertically or horizontally | – |

| Minimum gradient of the panels | – | min. 8,5 % |

| Heat transfer coefficient U (W/m²K) | 0,595–0,112 | 0,673–0,210 |

| Fire resistance | max. EW 60 DP3 | max. EW 120 DP1 |

| Anchoring of the panels | visible or invisible anchoring | |

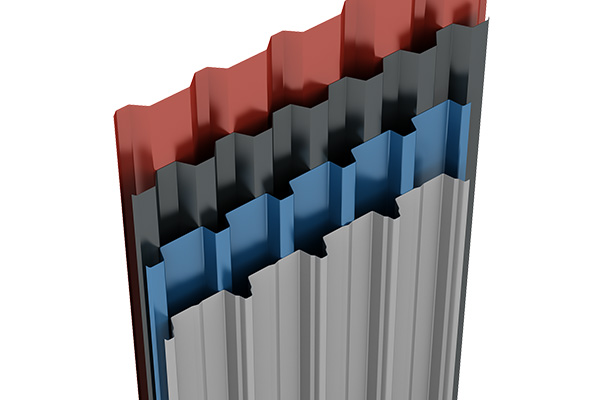

The combined cladding is an alternative to sandwich panels. It is a system of loadbearing waffles with additionally inserted heat insulation layer. The visible covering layer is usually made of trapezoidal plates.

Our company offers combined wall cladding for wall structures with high demands for fire resistance of wall cladding.

Wall cladding of facilities without the requirement for heat insulation properties is made of trapezoidal plates. This system is used mainly for industrial and agricultural warehousing facilities.

Trapezoidal wall plates are rolled of galvanized plates and they are provided with color coating. The color scheme can be selected from a wide range of colors.