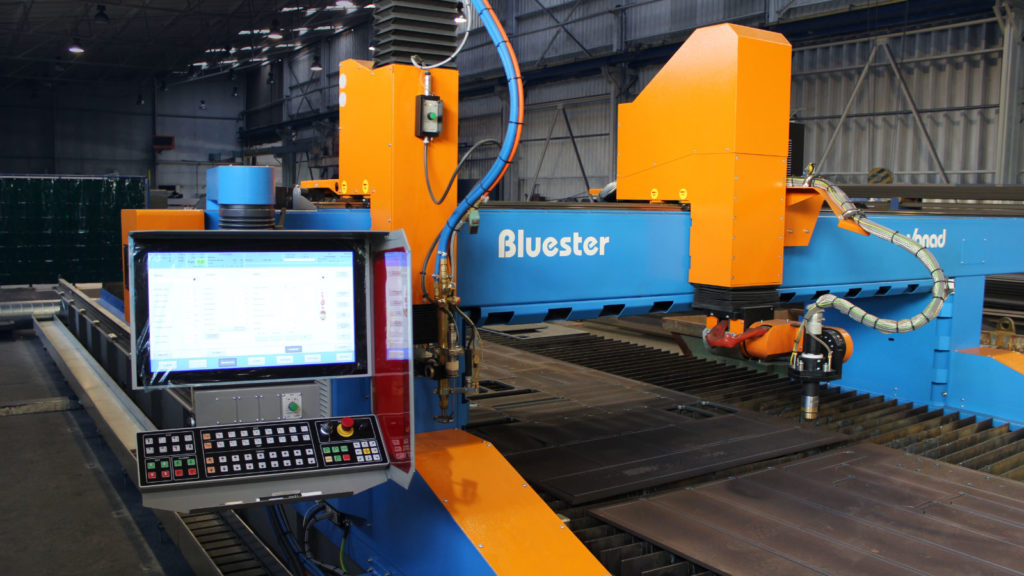

The automatic line consists of a tack welding line and the welding line. The initial dimensional arrangement of the combined section from partial steel elements is carried out on the initial tack welding line. The geometry of the section is secured by tack welds. The final welding line works with the preassembled section. After setting the basic parameters of the welding process the line will perform longitudinal continuous weld in the given position. The automatic line enables using two parallel welding torches.

The entire welding process is monitored by cameras and inspected by the welding line operators on the LCD monitor.

Welding on the automatic welding line enables fulfillment of all standardized requirements on the implemented welds and overall geometry of the combined section.