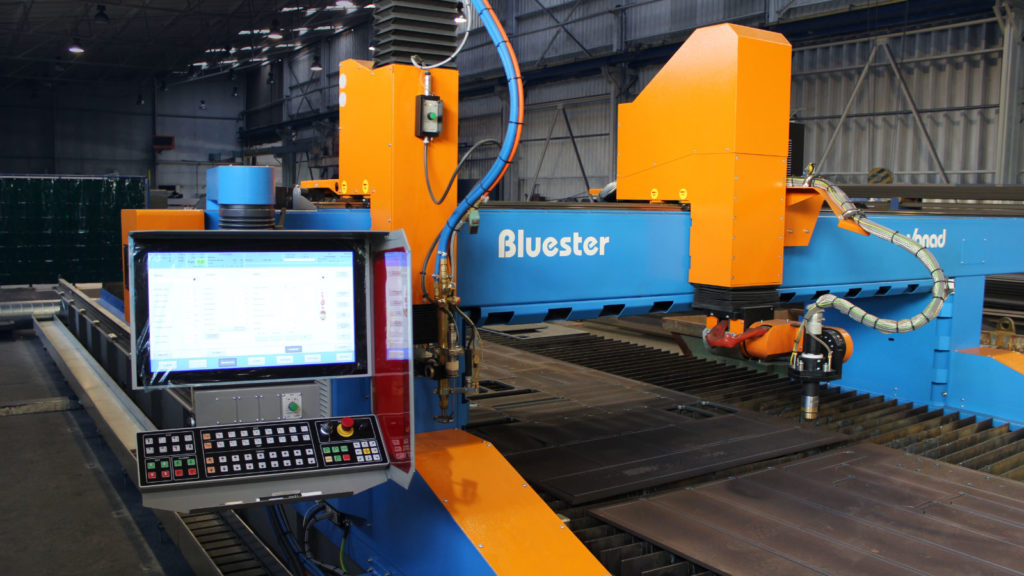

With the development of steel structures and materials, production itself and demands for technical processing and material modifications are also moving forward. Therefore, during the summer of 2018, our company FEMONT OPAVA s.r.o. expanded again in its own production, in particular with the new Thoman RB4 roll bending machine designed for the specific and design production of steel structures and secondary steel elements.

This flexible roll bending machine is used to bend pipes and closed profiles, and thanks to its high power, we are able to bend small and large steel and aluminum profiles with high bending moment.

The option of precise rollers adjustment allows us for an excellent way of bending profiles without damaging or deforming them. The machine is equipped with a measuring device for automatic correction of bends to achieve appropriate quality and accuracy according to customer requirements.

The final rolled product is thus always made with maximum precision and maximum quality while maintaining the technical properties of steel element.